Leadtech Printer-Leading Manufacturer in the Coding & Marking Industry since 2011.

Industrial Inkjet Coder Systems: What You Should Know

In today's industrial landscape, the use of inkjet coder systems is becoming increasingly crucial for efficient and accurate product coding. However, with the multitude of options available, it can be overwhelming to discern which system is best suited for your specific needs. In this article, we delve into the fundamentals of industrial inkjet coder systems and provide valuable insights into what you should know when considering this technology for your business. Whether you are an industry professional or a curious reader, this article will equip you with the essential knowledge to make informed decisions about inkjet coder systems.

Industrial Inkjet Coder Systems: What You Should Know

In today's fast-paced manufacturing industry, coding and marking products is an essential part of the process. Industrial inkjet coder systems are a popular choice for coding products, as they offer high-quality printing, fast speeds, and easy integration into existing production lines. If you're considering investing in an industrial inkjet coder system for your business, there are a few key things you should know before making a decision.

1. What are Industrial Inkjet Coder Systems?

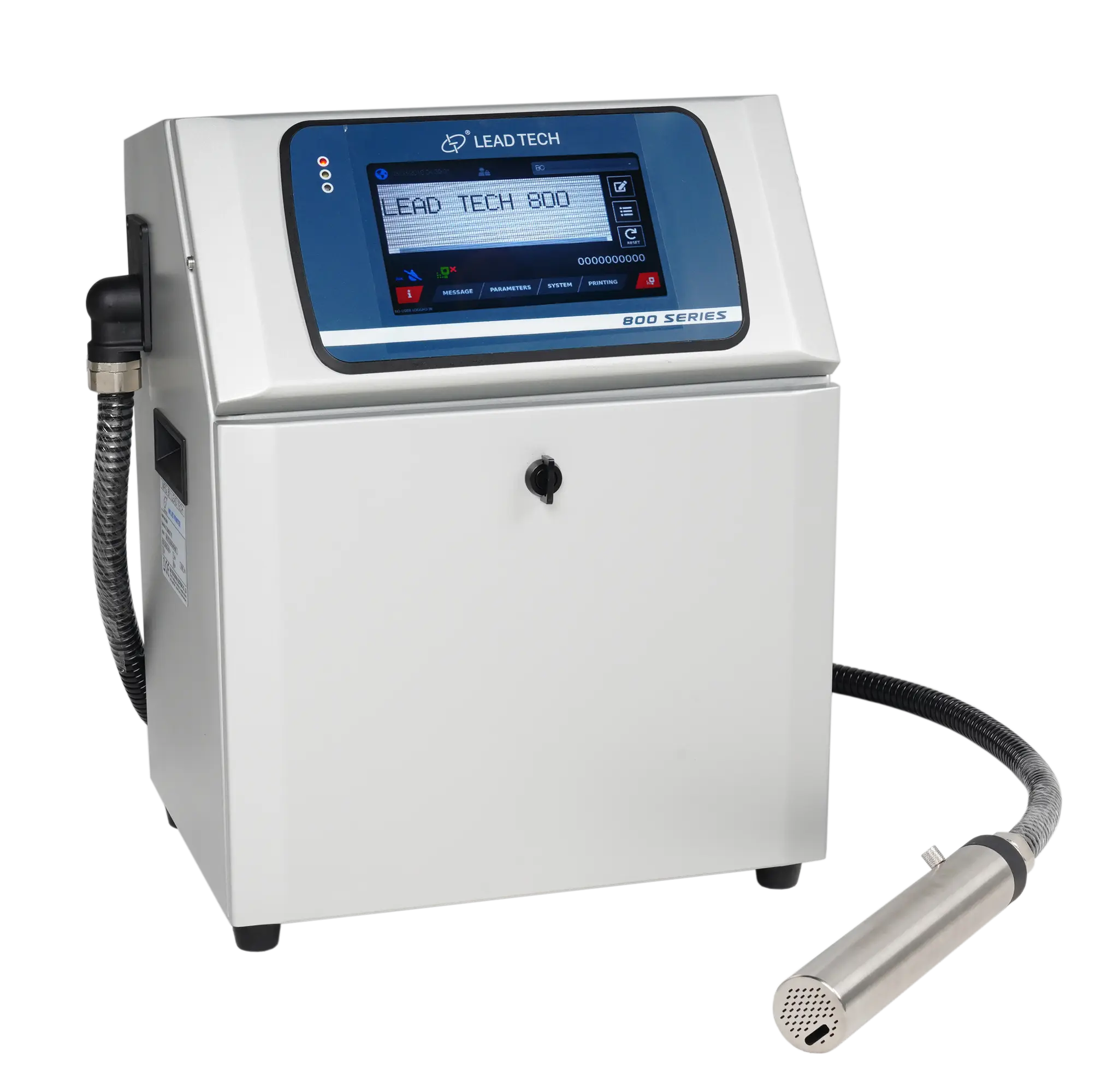

Industrial inkjet coder systems are advanced printing machines designed specifically for the industrial environment. Unlike traditional inkjet printers, which are commonly used for home or office use, industrial inkjet coder systems are built to withstand the rigors of continuous operation in a manufacturing setting. These systems use high-speed, high-resolution printing technology to mark products with text, barcodes, logos, and other information required for traceability and branding.

2. The Benefits of Industrial Inkjet Coder Systems

There are several benefits to using industrial inkjet coder systems in your manufacturing processes. First and foremost, these systems offer fast printing speeds, allowing for high throughput and increased productivity. They also provide exceptional print quality, ensuring that codes and markings are clear, legible, and long-lasting. Additionally, industrial inkjet coder systems are versatile, capable of printing on a wide range of substrates, including cardboard, plastic, metal, and glass. This versatility makes them suitable for use in a variety of industries, from food and beverage to pharmaceuticals and beyond.

3. Key Considerations When Choosing an Industrial Inkjet Coder System

When shopping for an industrial inkjet coder system, there are several key factors to consider. First, you'll want to evaluate the printing speed and resolution of the system to ensure it meets your production needs. You should also consider the size and flexibility of the printing space, as well as the type of inks and substrates the system is compatible with. Finally, it's important to assess the overall reliability and support offered by the manufacturer, as well as the total cost of ownership over the life of the system.

4. Why Choose Leadtech Coding?

When it comes to industrial inkjet coder systems, Leadtech Coding is a name you can trust. Leadtech Coding offers a wide range of industrial inkjet coder systems, designed to meet the unique needs of different industries and production environments. Whether you're looking for a compact, entry-level system or a high-speed, high-resolution solution, Leadtech Coding has a product to suit your requirements. In addition to offering top-quality products, Leadtech Coding provides comprehensive customer support, including installation, training, and ongoing maintenance services, to ensure that your investment delivers maximum value.

5.

In conclusion, industrial inkjet coder systems are a valuable tool for modern manufacturing operations, offering fast, high-quality printing and versatile use across various substrates. When selecting an industrial inkjet coder system for your business, it's essential to consider key factors such as printing speed, resolution, flexibility, and total cost of ownership. With the right system in place, you can improve productivity, enhance traceability, and meet the coding and marking requirements of your industry. And with Leadtech Coding as your partner, you can trust that you're getting a reliable, high-quality solution with expert support every step of the way.

Conclusion

In conclusion, industrial inkjet coder systems are a crucial part of many production processes and can offer numerous benefits to manufacturers. From their ability to code on a variety of surfaces to their high-speed and accurate printing capabilities, these systems provide a valuable tool for ensuring efficiency and consistency in product coding. By understanding the different types of inkjet coders available, as well as their key features and maintenance requirements, manufacturers can make informed decisions about which system will best suit their specific needs. Ultimately, investing in the right industrial inkjet coder system can lead to improved productivity, cost savings, and overall success in the production environment.