Leadtech Printer-Leading Manufacturer in the Coding & Marking Industry since 2011.

Leading Laser Marking Machine For Metal: High-Performance Solutions For Industrial Use

Welcome to our in-depth exploration of the leading laser marking machine for metal. In this article, we will delve into the high-performance solutions that are revolutionizing industrial metal marking. Whether you are a manufacturer, engineer, or simply curious about the latest advancements in metal marking technology, this article will provide valuable insights and information. Join us as we examine the cutting-edge features and benefits of these innovative machines and discover how they are enhancing efficiency and precision in industrial applications.

Leading Laser Marking Machine for Metal: High-Performance Solutions for Industrial Use

As technology continues to advance, the demand for high-performance solutions in the industrial sector has never been greater. When it comes to metal marking, laser technology has revolutionized the way manufacturers and industrial professionals approach the permanent marking of metal components. The market is filled with a wide range of laser marking machines, but not all are created equal. For those seeking the best in class, Leadtech Coding offers a leading laser marking machine for metal that delivers superior performance and precision.

Introducing Leadtech Coding: A Name You Can Trust

With a strong focus on innovation and customer satisfaction, Leadtech Coding has established itself as a trusted name in the industrial marking industry. For years, our team of experts has worked tirelessly to develop cutting-edge solutions that meet the unique needs of our clients. When it comes to laser marking machines for metal, our commitment to quality and performance is unmatched.

The Benefits of Laser Marking for Metal Components

Laser marking has quickly become the preferred method for marking metal components in the industrial sector. The process involves using a high-powered laser to engrave or etch marks onto the surface of the metal. This method offers several key advantages over traditional marking techniques, including:

1. Permanent and High-Quality Markings: Laser marking produces highly durable and precise markings on metal components, ensuring that the information remains legible and intact for the life of the product.

2. Versatility: Laser marking is capable of marking a wide range of metals, including stainless steel, aluminum, titanium, and more. This makes it an ideal solution for industries with diverse marking needs.

3. Speed and Efficiency: Laser marking machines can achieve high marking speeds, allowing for quick and efficient processing of metal components. This makes it a perfect fit for high-volume industrial applications.

4. Cost-Effectiveness: While the initial investment in a laser marking machine may be higher compared to traditional marking methods, the long-term cost savings are significant. Laser marking eliminates the need for consumables such as inks and dyes, reducing ongoing costs.

5. Environmental Friendliness: Laser marking is a non-contact process that does not produce any waste or harmful emissions, making it an environmentally friendly marking solution.

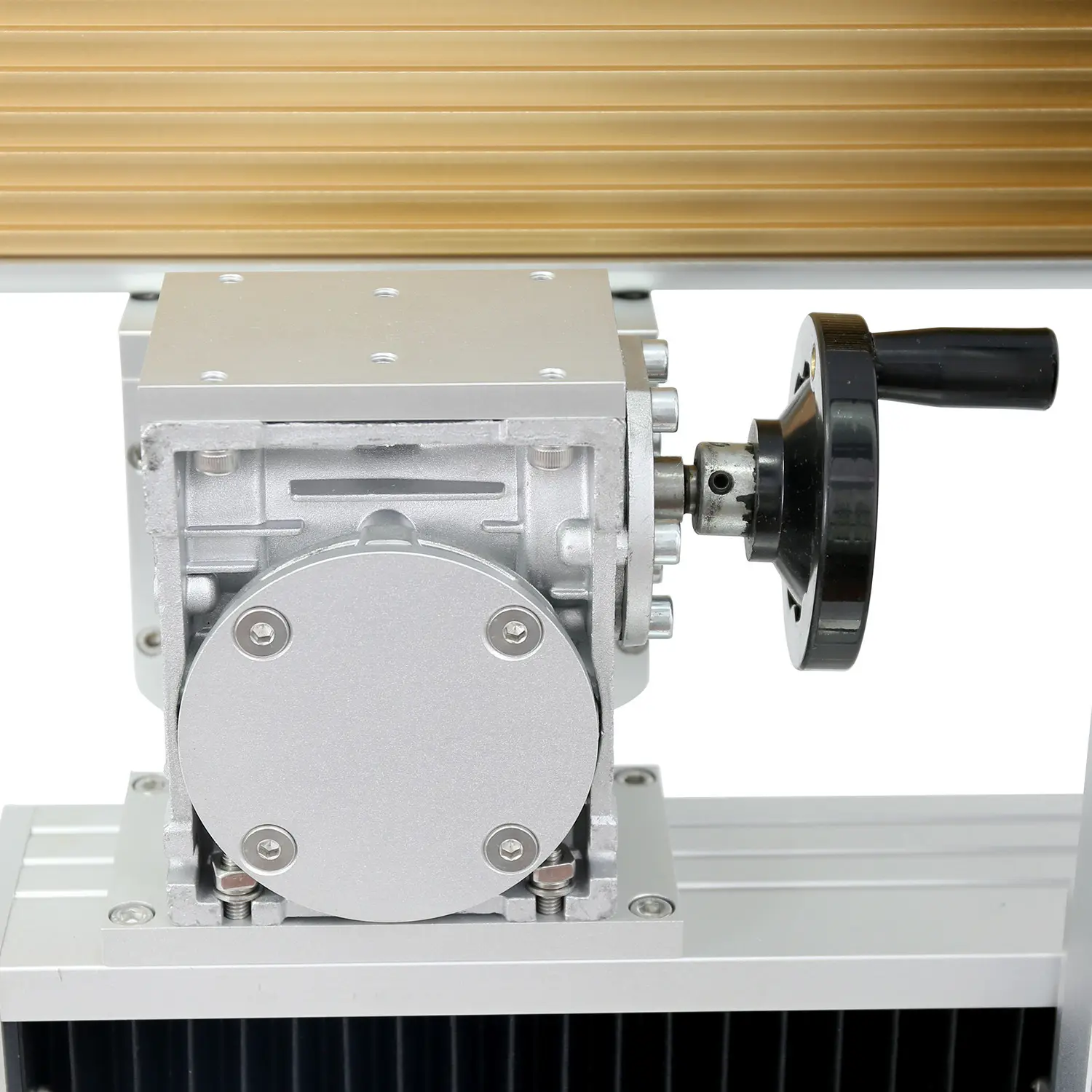

Leadtech Coding’s High-Performance Laser Marking Machine for Metal

At Leadtech Coding, we take pride in offering a high-performance laser marking machine specifically designed for metal marking applications. Our laser marking machines are engineered to deliver exceptional speed, precision, and reliability, making them ideal for a wide range of industrial uses.

Key Features of Leadtech Coding’s Laser Marking Machine for Metal:

1. Advanced Laser Technology: Our machines utilize the latest in laser technology to ensure precise and consistent marking on metal surfaces.

2. High-Speed Marking: With rapid processing capabilities, our laser marking machines are capable of handling high-volume marking tasks with ease.

3. User-Friendly Interface: Our machines feature an intuitive interface that makes operation and maintenance simple and efficient, reducing downtime and maximizing productivity.

4. Customizable Marking Options: Our laser marking machines offer flexibility in marking styles, including text, graphics, and barcodes, allowing for customization to suit individual industry requirements.

5. Durable and Low-Maintenance Design: Leadtech Coding’s machines are designed for durability and minimal maintenance, ensuring long-term reliability for industrial use.

For industrial professionals seeking a reliable and high-performance laser marking solution for metal components, Leadtech Coding’s laser marking machine stands out as the ideal choice. With a strong commitment to quality and customer satisfaction, Leadtech Coding continues to lead the way in providing innovative solutions that meet the evolving needs of the industrial market.

Conclusion

In conclusion, the leading laser marking machines for metal offer high-performance solutions for industrial use. These machines provide precision, speed, and reliability, making them essential tools for a wide range of applications in the manufacturing and industrial sectors. With their advanced technology and capabilities, these machines are able to meet the demanding requirements of industrial marking, ensuring clear and durable markings on metal surfaces. As technology continues to advance, the future of laser marking machines for metal looks promising, with even more innovative and high-performance solutions on the horizon. With their ability to deliver consistent and high-quality results, these machines are truly indispensable for any industrial application that requires precision marking on metal.